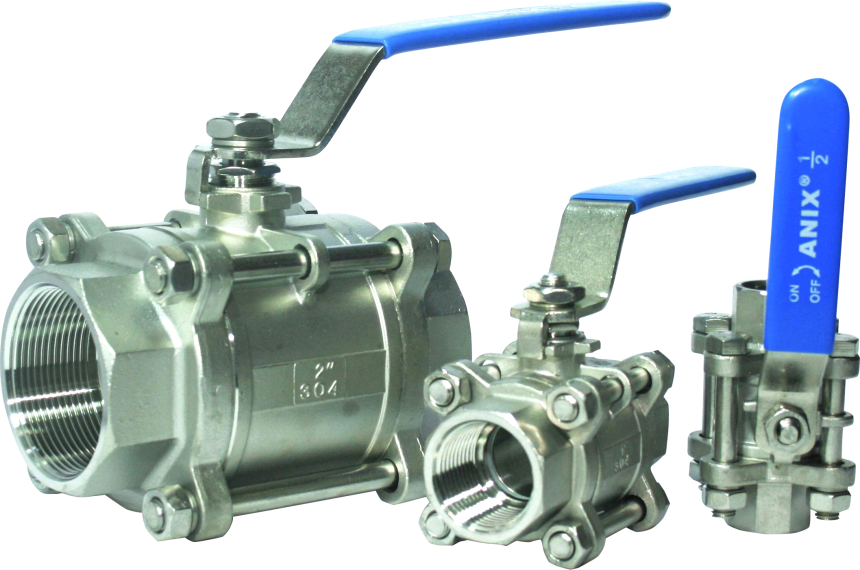

Mechanical engineers take great care in designing machinery and systems with maximum functionality in mind, including valve contacts. Valve contacts play an essential part in controlling fluid or gas flows within systems; one notable name in this regard is Anix Valve Contacts – in this article, we explore their significance, various types, uses, and more!

Understanding Anix Valves

Anix Valves are known for their superior quality and performance. Their primary function is to protect fluid or gas flow within mechanical systems by acting as gatekeepers to make sure only necessary substance passes through without leakages or irregularities.

Valve Contacts Anix Valves’ Valve Contacts are essential components to their proper function; these components control when and how the valve opens or closes, thus contributing to overall system efficiency and safety. Their operation must remain functional to maintain system effectiveness.

Anix Valves feature various kinds of valve contacts, such as ball valves, butterfly valves, and gate valves. Each has its own set of advantages and applications that make selecting the appropriate one essential to any given system.

Considerations When Selecting Valve Contacts

Finding an appropriate valve contact requires considering several factors, including pressure, temperature, and substance type that will pass through it. Finding an optimal match will prevent malfunction or damage to equipment that uses this valve contact system.

Anix Valve Contacts are frequently utilized across a range of industries, from oil and gas production to chemical, pharmaceutical, and water treatment applications. Their versatility and dependability make them suitable for many diverse situations.

Maintaining and Troubleshooting Valve Contacts

Regularly service valve contacts to maximize their lifespan and efficiency, and promptly troubleshoot any problems that arise to minimize unnecessary downtime costs.

Anix Valve Contacts Offer Multiple Advantages

Anix Valve Contacts can bring several advantages, including improved system control, lower maintenance costs, and enhanced safety features. Their design meets industry-wide standards to meet them with excellence.

Anix Valve Contacts are produced by several reputable manufacturers and suppliers; therefore it’s essential that when selecting one as your source it ensures the quality and authenticity of the product.

Installation Guide of Anix Valve Contacts

A proper installation is of utmost importance to maximize Anix Valve Contact performance and achieve its full potential. Adherence to manufacturer recommendations and best practices are crucial components to its successful use.

Innovation in Valve Contact Technology

Valve contact technology is constantly developing. Staying abreast of these advancements can result in more efficient and cost-effective solutions for valve contacts.

Anix Valve’s commitment to producing eco-friendly solutions and making informed choices. As consumers is increasing environmental consciousness and contributing to sustainability.

Conclusion

Anix Valve Contacts are essential in the smooth operation of mechanical systems. Their versatility of applications and superior quality make them one of the leading products on the market, and understanding and choosing one suited to your specific requirements can improve both its performance and durability over time.